May 29,2024

Plastic Sheet Piling is a new material that has many advantages over hard wood, concrete and steel sheet piling. It is durable, light-weight, aesthetic and corrosion resistant.

It also provides an environmentally friendly building material with a long service life without toxic coatings or preservatives. It is used for sustainable water barriers at harbours and cut-off walls for flood protection.

The modern sheet pile industry is about 100 years old and has seen some significant changes in product selection and manufacturing over the past decade. Competitive factors have led to a number of development programs including wider, more-efficient sections with section modulus up to twice that available previously.

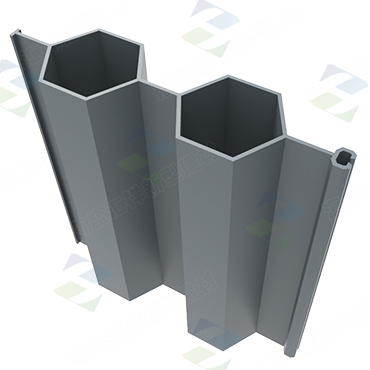

A wide variety of designs can be manufactured in a range of widths, including heavy duty wall systems where bending strength governs the design and no deflection (swing) between sheets is required. These products can be pultruded or laminated to form a section of constant cross section, with multi-directional reinforcement of long continuous glass fibres (roving) and matting woven into the sheet.

Installation is typically carried out with driving equipment. A wide variety of hammers, from Movac-type side grip rigs through to excavator mounted vibratory and light crane suspended vibratory/air hammers can be employed depending on soil conditions. Under certain circumstances high pressure air or water jetting may be applied to augment the driving process. In some cases a protective steel cap or mandrel may be used to protect the head of the sheet pile.

English

English 中文简体

中文简体